■ Product Advantages

■ Powder Cutting Packagingstatic Elimination System

01/02 Cylindrical/vertical electrical dissipator

System Composition

The powder electrostatic elimination system is mainly composed of two parts: the controller and the ionic air discharger.

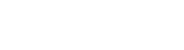

▲ Electrical connection diagram

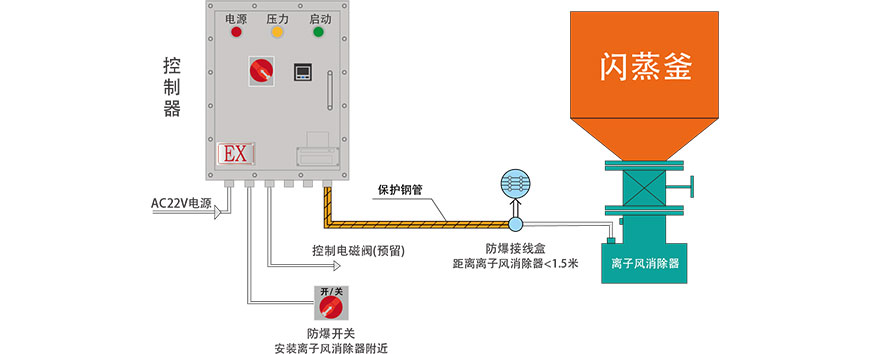

▲ Air supply connection diagram

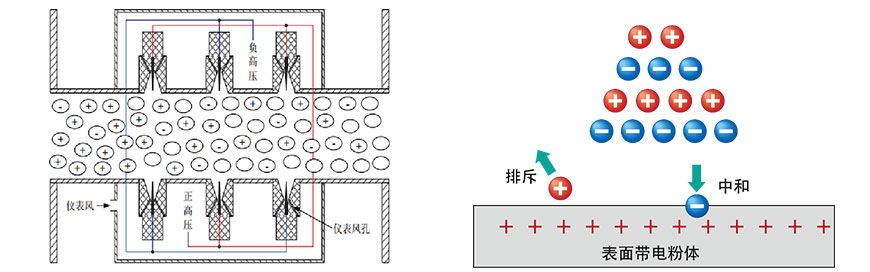

Principle of Electricity Consumption

The basic working principle of the ion wind electrostatic eliminator is to ionize the air into positive and negative ions through the high voltage corona discharge at the tip of the ion nozzle of the ion generator, and the corresponding polar ions are then transported to the surface of the charged material by the action of the electric field force to achieve electrical neutralization, thus eliminating the charge carried by the powder.

The adjacent ion nozzles of the ion generator simultaneously emit ions of opposite polarity, forming an approximately neutral ion cloud in the region through which the powder passes. When the powder with static charge passes through the port, it will produce an electrostatic field. Under the action of this electric field, the ions in the neutral ion cloud with the opposite polarity of the powder will flow to the powder rapidly due to the action of the electric field force, while the ions in the neutral ion cloud with the same charge polarity of the powder will flow away from the direction of the powder due to the action of the electric field force. Therefore, under the action of the electrostatic field of the powder, the neutral ion cloud generated by the electric dissipator automatically balances the electrostatic charge of the powder. For electrostatic hazards in the process of polyolefin discharge packaging, the electrostatic field self-balancing ion injection is enough to make the electrostatic potential on the surface of the bag drop below the national electrostatic safety management index when the powder is directly bagged.

Technical Parameter - Controller

● Explosion-proof mark: ExdIIBT6Gb

● Rated voltage: AC220V±10%

● Rated current: 0.5A

● Power frequency: 50Hz

● Power supply: 100W

● Shape volume: 616mm×420mm×180mm (width/height/thickness)

Technical Parameter - Ionic air dissipator

● Explosion-proof mark: Ex pzc IIB T6 Gc; Ex pzc IIIC T80℃ Dc

● Rated voltage: DC12V±10%

● Corona voltage: 8kV±10%

● Power dissipation range: 0 ~ ±10.0μC/kg

● Protective gas: instrument compressed air or nitrogen

● Gas pressure: 0.3 ~ 0.6MPa

● Minimum airflow: 20L/min

● Power off pressure: 5kPa

● Power dissipation efficiency: power dissipation rate ≥90%, or ton bag surface potential < 15KV

Application site

▼ Cylindrical ionic damper application diagram + vertical ionic damper application diagram

03 Controller

03 Controller

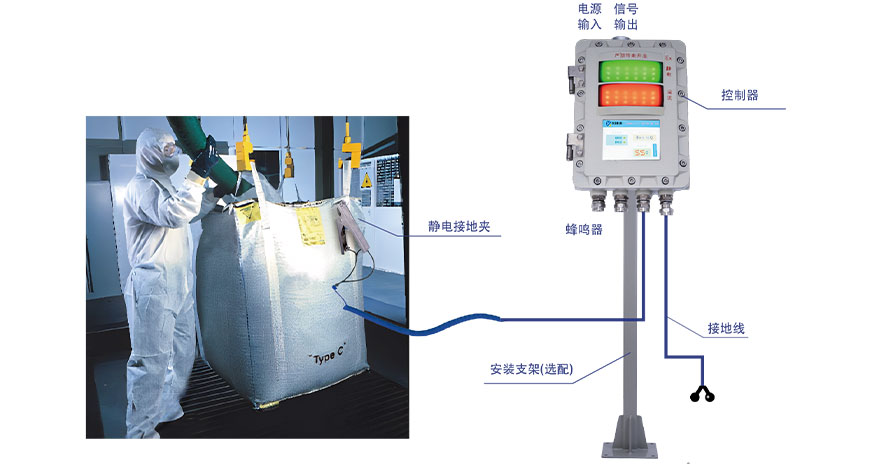

In the flammable and explosive or combustible dust environment, a large amount of static electricity will be generated during the loading and unloading of bulk materials due to friction.

To prevent electrostatic discharge, take the following measures:

● Use type C container bags (conductive container bags/anti-static container bags)

● The charge generated by the pack needs to be quickly discharged

In order to deal with such problems, our company developed the anti-static interlocking controller of the container bag, which can make the static electricity on the container bag quickly discharge, and eliminate the possibility of combustion or explosion caused by friction electricity during loading and unloading.

Special electrostatic grounding clip does not damage the ton bag, and increases the contact area. Can prevent traction off, vibration off, mechanical spark, to ensure low resistance connection.

Technical Parameter

● Explosion-proof class: Ex dbia [iaGa] IIB T6Gb; Ex ia tb ⅢC T80°C Db

● Protection grade: IP65

● Working voltage: AV220V±10%

● Alarm resistance: 0-100ω adjustable

● Alarm mode: sound and light alarm

● Response time: < 1S

● Output signal: relay output, normally open, normally closed dry node

● Interface capacity: 10A,30V DC; 10A,250V DC

Four security guarantees

● Authoritative explosion-proof certification, intrinsic safety design;

● Interlocking control, grounding abnormal interlocking automatic shutdown operation;

● Special electrostatic grounding clamp to prevent bad contact and mechanical sparks;

● PU cable, wear-resistant, corrosion-resistant, anti-static.

▲ Field use diagram